reason #1

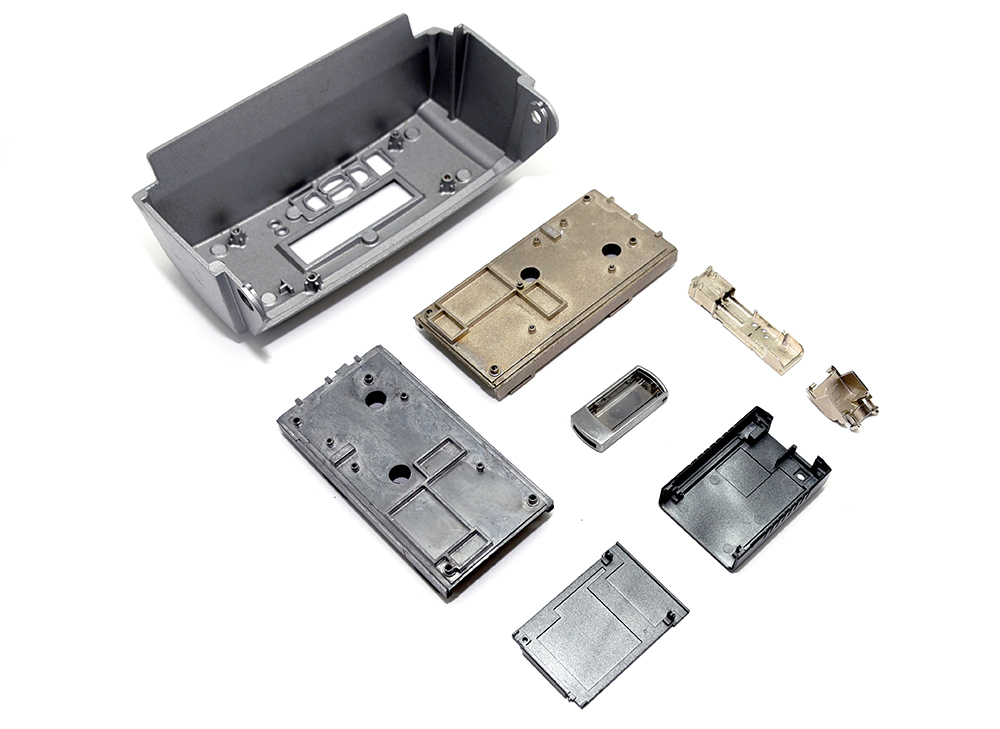

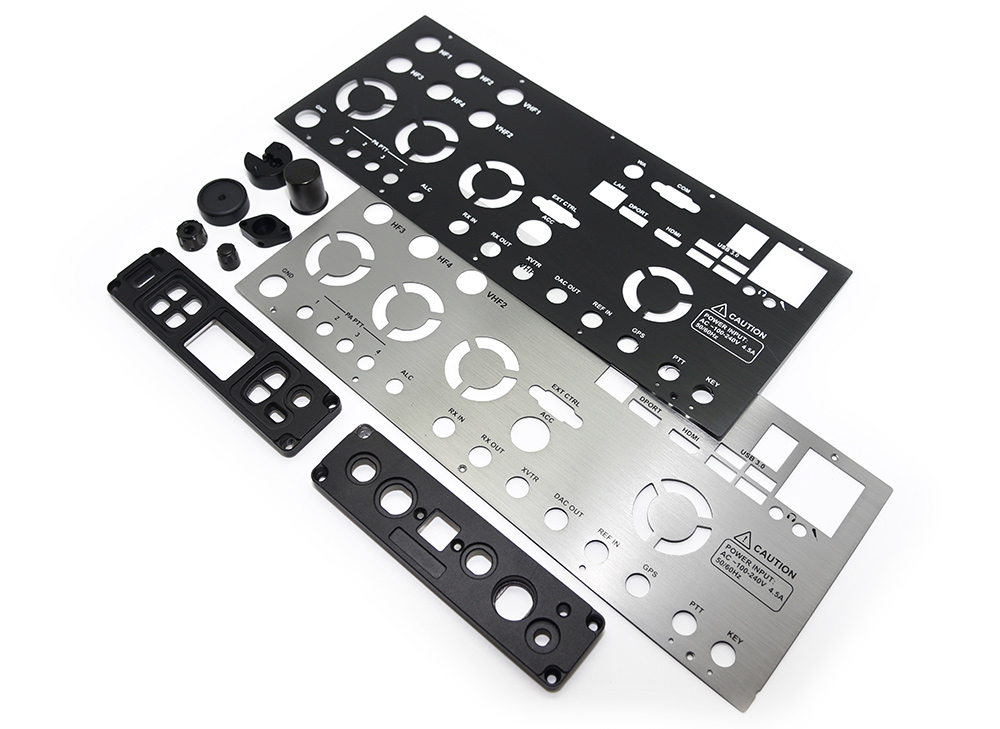

Design Development

From your ideas to finished successful products — its our duty. Starting from sketch to long term 2D and 3D industrial design and ending with complex tooling and mass production. We can bring your concepts to life using existing materials and known technologies.

reason #2

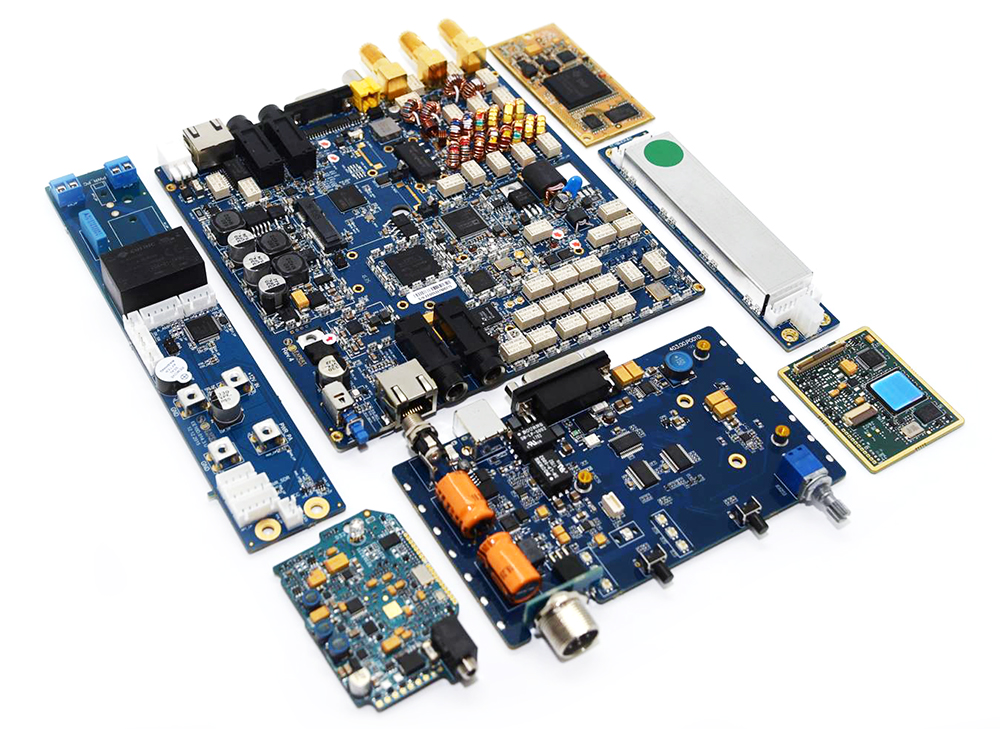

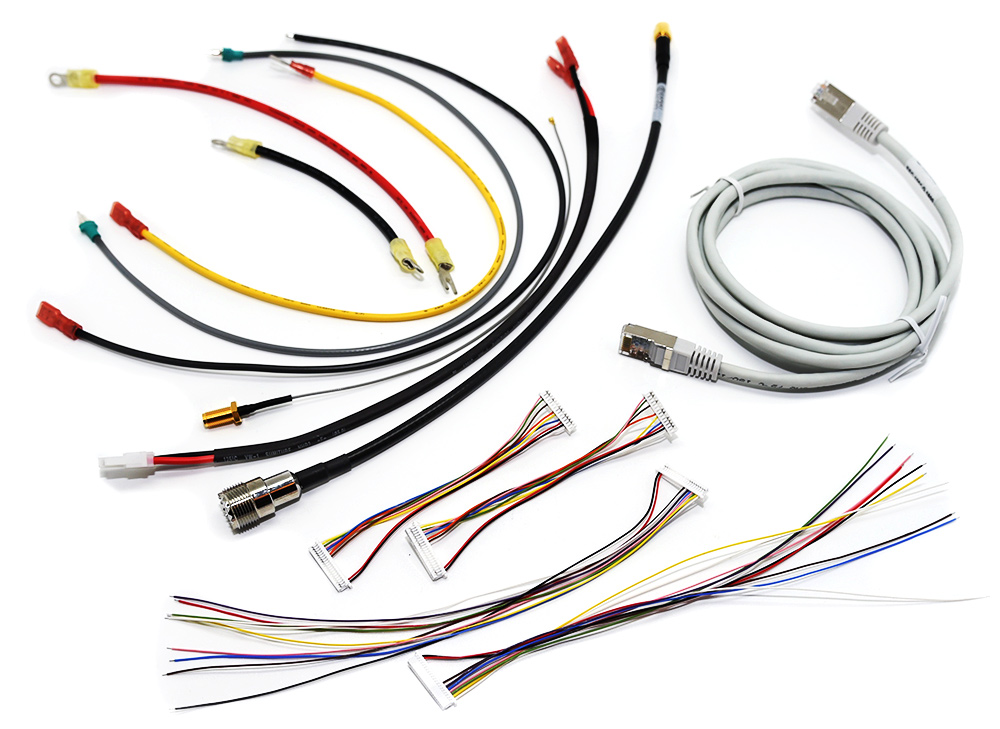

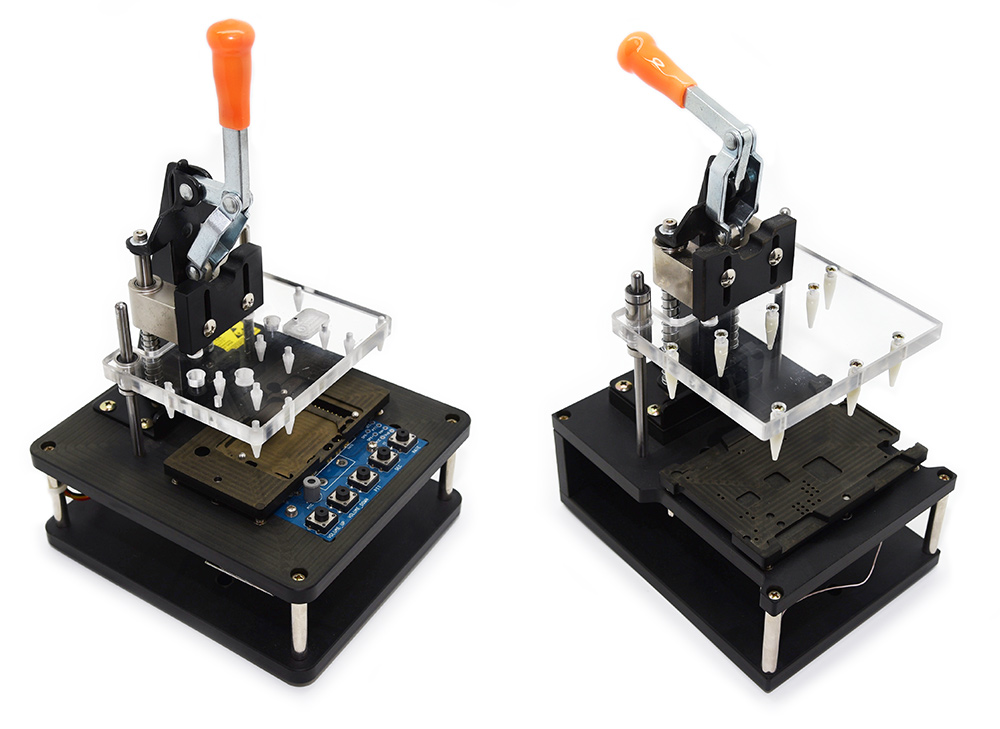

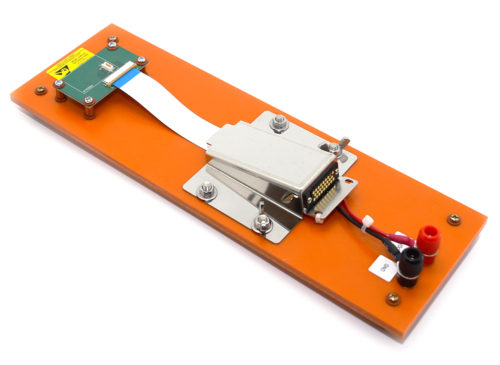

System Integration

Modern electronics are very complicated - various technologies, materials and other details, modern electronics are closely connected with other industries and everyday life activities of the modern society, possessing a wide range of knowledge and creative thinking we perform intricate technical tasks using extraordinary solutions in solving complex problems.

reason #3

Quality Assurance

We are only using brand components, and high-quality materials, processing and assembling on modern machines with a high production manner. We do ensure quality control at all stages of manufacturing. The final QA inspection, according to customer requirement, includes: burn-in tests, environment-thermocycling test reliability test, salt-spray test, UV-test, waterproof test, drop-test, vibration test, hazardous substances analyses such as Cd, Pb and others, if necessary.

reason #4

Components

Selection & Sourcing

Global network of distributors and strong relations with suppliers allow us to provide the most competitive prices to our customers, flexible terms and conditions We also provide technical support to optimizes BOM lists, quickly replace EOL components which are discontinued or the delivery time does not correspond to the production schedule.

reason #5

Technologies

& Materials Searching

Our suppliers' factories and technoparks are within walking distance and are always open for consultation. Our experience all of which we successfully utilize, modern know-how techniques and materials help us and our customers discover new horizons and understand what modern devices can be like.

reason #6

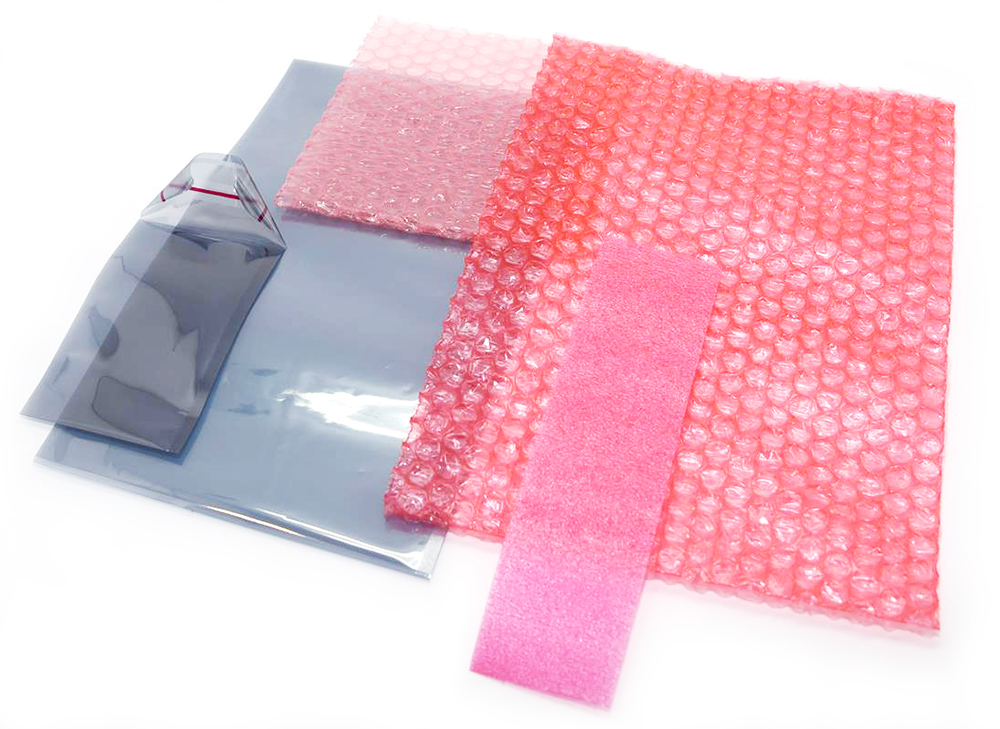

Logistic Fulfilment

We ship to the customer or end user, according to the contract with the customer, anywhere in the world. We work with the most famous cargo carriers air, cargo, shipment by sea. We guarantee the correctness of registration of customs documents and compliance with certificates. Methods of sending are discussed in advance with the client. We guarantee delivery to you in a convenient way, within the specified terms.

reason #7

International

Certification & Licensing

We do complete all necessary procedures in case of deviation of parameters from required characteristics , we take an active part in finding a solution and obtaining a certificate. For certification, we only use laboratories in Taiwan. At the stage of procurement of components and materials, we strictly follow that all elements comply with the requirements of ROHS or Reach standards.

reason #8

Warranty Support

& Repairing

Service support and repair is a part of our work which is just as necessary and is crucial for a successfully developed business. Our service center provides repair and warranty service, the supply of spare parts and essential components for repairs. Warranty maintenance will be carried out according to bilateral agreements or contract conditions.

JDMS & EMS

(Joint Design Manufacturing Solutions & Electronics Manufacturing

Service)